But behind every well-organized warehouse or store, there is a process that goes unnoticed, a process commonly known as receiving inventory. Usually, when items are late, damaged, or misclassified upon arrival, it causes issues throughout a complete business, from a shortage of stocks to a decrease in profit due to customer dissatisfaction. Therefore, a modern business is revisiting how it handles its inventory even from the first point of contact.

Receiving inventory has become more than just unloading a box and a signature on a document. It is a function of precision, speed, accountability, and visibility. It is firms that view receiving as a strategic process rather than a repetitive activity that scale more quickly and make better operational choices.

At the receiving stage, businesses confirm quantities, inspect goods, update stock levels, and trigger internal workflows. Even a small mistake here can create long-term problems: incorrect stock counts, delayed order fulfillment, or wasted labor hours trying to reconcile errors later.

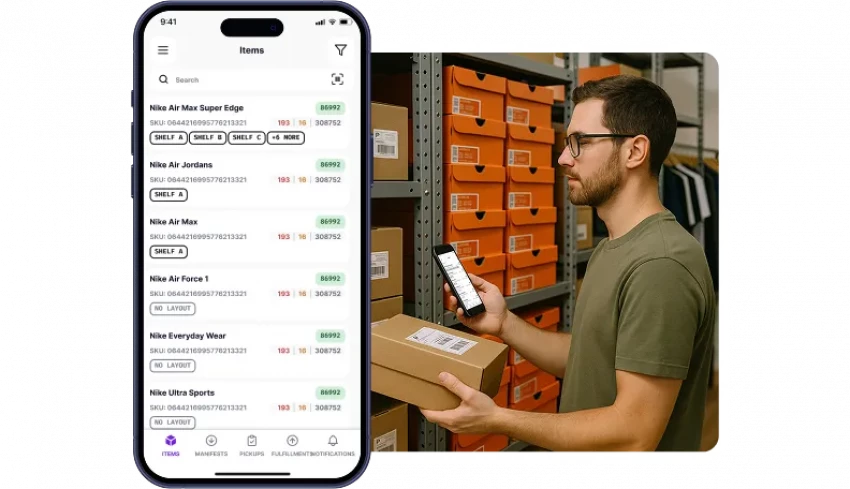

This is where inventory receiving software becomes a game-changer. Instead of relying on spreadsheets, handwritten notes, or disconnected systems, teams can digitize the entire process. Items are scanned as they arrive, quantities are verified in real time, and discrepancies are flagged immediately not days or weeks later.

For example, a mid-sized e-commerce warehouse that previously spent hours correcting inventory mismatches can reduce those errors dramatically by logging items at the dock. Staff know instantly whether a shipment matches the purchase order, and managers get live visibility into what’s actually available for sale.

Usually, a manual process for receiving involves reliance upon memory, paper documents, or a speedy entry process, all of which are contributing factors to human error. Electronic receiving process routes add accountability because every process followed, with a timestamp, relates to a user or a shipment.

Such transparency is particularly important for companies dealing with large volumes or multiple suppliers. For instance, whenever a problem arises, it is easy for them to identify where things went wrong, a supplier problem, a product that arrived damaged, or a company problem.

In the manufacturing or wholesale segments, such traceability can also help with compliance and audit or quality assurance tasks.

Accurate receiving data doesn’t just help operations it feeds smarter decision-making across the business. When inventory data is reliable from the moment goods arrive, forecasting becomes more precise, purchasing decisions improve, and overstocking or stockouts are easier to avoid.

Many companies also use documented research or internal guidelines to standardize receiving processes. For instance, teams may cite a PDF as a reference when training new staff or aligning procedures across multiple locations. Having clear, documented standards combined with digital tools ensures consistency no matter who is on shift or where inventory is received.

Consider a retail chain expanding to multiple warehouses. Without a standardized receiving system, each location might handle deliveries differently, leading to inconsistent data and frequent inventory discrepancies. By aligning processes and tools, the business creates a single source of truth across all locations.

The result? Faster onboarding for new employees, fewer disputes with suppliers, and more confident planning for sales campaigns and promotions.

If you’re looking to optimize inventory receiving, start with these actionable steps:

● Standardize procedures so every team follows the same checklist

● Train staff regularly, especially during peak seasons

● Verify shipments immediately instead of postponing checks

● Document exceptions like damaged or missing items on the spot

● Review receiving data weekly to spot patterns or recurring issue

Small improvements at the receiving stage can unlock significant gains across your entire supply chain.

Inventory success doesn’t begin on the sales floor or at checkout it begins the moment goods arrive. By treating receiving as a strategic process and supporting it with the right tools, businesses gain accuracy, control, and confidence in their operations. When inventory data is correct from day one, everything that follows becomes easier, faster, and more profitable.

Be the first to post comment!